|

Ningbo Yinzhou Hongyong Machinery Factory

|

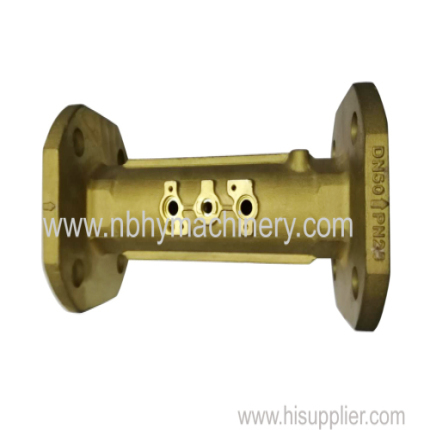

6 axis cnc machine parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery Factory is a professional OEM Injection Molding & Metal Fabrication factory located in Ningbo,CHINA and specialize in this field. Our main business is CNC Machining, plastic injection molding,and stamping parts. We now have sophisticated CNC machining center, Laser cutting machine,Milling machine,Punch press 6.3 to 160 T,Assembly line,Hydraulic bending machine,Welding machine and other equipments.

Our dedicated test and inspection department features the following equipment:Pin gauge,Indicator,Granite Surface Plate,Micrometer ID/OD,Video measurement (profile projector),Caliper digital,Block gauge,Coordinate measuring machine (CMM),etc.It is a strong support for our pursuit of quality. Our main export markets: Europe,Asia,Africa,Qatar,El Salvador,Netherlands Antilles,Paraguay,Antigua and Barbuda,Guadeloupe,etc. And the payment terms is T/T, L/C, D/P.

6 axis cnc machine parts:

Customized Design

Sample Order Accepted

Short Delivery time

Competitive Prices

Long time quality Insurance

Professional after-sale services

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

This is our workshop and equipment

6 axis cnc machine parts---FAQs Guide

1.What is the accuracy and repeatability of 6 axis cnc machine parts?

2.Are 6 axis cnc machine parts subjected to heat treatment or surface treatment to enhance their performance?

3.How does the manufacturing process and process of 6 axis cnc machine parts affect their quality and accuracy?

4.Is 6 axis cnc machine parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

5.How do 6 axis cnc machine parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

6.How can 6 axis cnc machine parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

7.Are there 6 axis cnc machine parts suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

8.What is the strength and rigidity of 6 axis cnc machine parts, suitable for high load applications?

9.How can 6 axis cnc machine parts respond to voltage and power standards in different regions and countries?

10.What is the data collection and monitoring function of 6 axis cnc machine parts to improve production traceability and control?

11.How can 6 axis cnc machine parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

1.What is the accuracy and repeatability of 6 axis cnc machine parts?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

2.Are 6 axis cnc machine parts subjected to heat treatment or surface treatment to enhance their performance?

Yes, 6 axis cnc machine parts can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

3.How does the manufacturing process and process of 6 axis cnc machine parts affect their quality and accuracy?

The manufacturing process and process of 6 axis cnc machine parts affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

4.Is 6 axis cnc machine parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, 6 axis cnc machine parts are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

5.How do 6 axis cnc machine parts handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our 6 axis cnc machine parts business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

6.How can 6 axis cnc machine parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the 6 axis cnc machine parts industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

7.Are there 6 axis cnc machine parts suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

Yes, 6 axis cnc machine parts can be used to manufacture special precision measurement and calibration equipment. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape materials into precise shapes and sizes. CNC machining can be used to create parts with tight tolerances and intricate details, making it ideal for precision measurement and calibration equipment.

8.What is the strength and rigidity of 6 axis cnc machine parts, suitable for high load applications?

The ability of metal materials to resist elastic deformation under stress and The ability of metal materials to resist plastic deformation and fracture under external forces.

9.How can 6 axis cnc machine parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

10.What is the data collection and monitoring function of 6 axis cnc machine parts to improve production traceability and control?

We focus on providing high 6 axis cnc machine parts quality products and services.

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

11.How can 6 axis cnc machine parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.