|

Ningbo Yinzhou Hongyong Machinery Factory

|

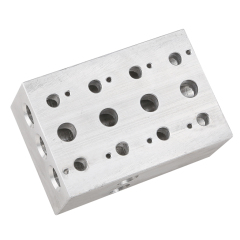

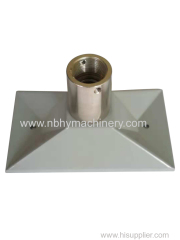

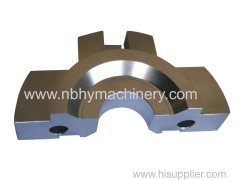

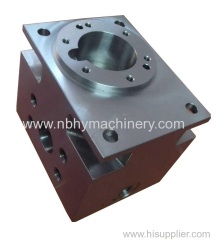

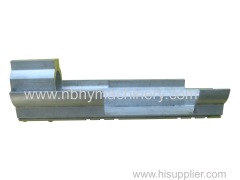

cnc machine parts product

| Payment Terms: | T/T,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

CNC machine parts refer to the components that make up a CNC machine. These machines are used in various industries for tasks like precision cutting,

Product Attribute

Packing:Delivery Date:Supply:Material:Weight:Machining:Surface Finish:

| Wooden Case/Pallet | 32-37days after the... |

| Drawing Design or OEM | Carbon Steel |

| 0.27kgs | Machining Center |

| white zinc-plating |

Product Description

| 1 | Business Type: | OEM& ODM Manufacturer |

| 2 | Products Range: | Auto /Moto Parts, Machinery Parts, Hardware Accessories, Furniture Hardware etc |

| 3 | Materials: | Aluminum: AL6061, AL6082, AL7075, AL5052, etc |

| Steel: S355ML, S420ML, P20, SKD11, SKD61, SKH9, SKH51, S45C, etc | ||

| Iron: 1C45, Y15, C1211, SUM2212L14, 1215, etc | ||

| Stainless steel: SUS304, SUS303, SU316L, SUS440C, etc | ||

| 4 | Machining: | cleaning, turning, milling, drilling, grinding ,CNC shearing,laser cutting, welding etc |

| 5 | Surface Treatment: | Polishing, Deburring, Chrom Plate, Ni Plated, Zine plated, Silver platinng |

| Clear anodizing, Anodizing black, Carburizing Nitriding, Heat Treatment, etc | ||

| 6 | Testing Equipment: | Hexagon CMM, TESA Height Gauge, Projector, Micrometer, etc |

| 7 | QC System: | 100% Inspection before shipment |

| 8 | Payment Term: | T/T, L/C, D/P |

| 9 | Trade Terms: | FOB, CIF |

| 10 | Delivery Time: | 20-30Days(According to The Order) |

| 11 | Our Advantages: | Reliable Quality |

| Competitive Price | ||

| High precision, high quality, tight tolerance | ||

| Continuous Improvement | ||

| On-Time Delivery | ||

| Customer Satisfaction | ||

| Excellent After-Sales Service |

Tags: cnc machine parts

How do different parts in CNC machine work together to ensure high-precision machining and manufacturing processes?

Different parts in a CNC (Computer Numerical Control) machine work together in a coordinated manner to ensure high-precision machining and manufacturing processes. Here's how these parts collaborate to achieve this:

Control Software: The CNC machine operator or programmer creates a design and translates it into G-code instructions using control software. This software generates a toolpath that guides the machine's movements.

Control Panel and Input Devices: The operator uses a control panel equipped with input devices, such as a keyboard or touchscreen, to input the program, select the right tools, and make necessary adjustments. This interface allows for precise control.

Processor: The CNC machine's processor (usually a computer or microcontroller) interprets the G-code instructions and coordinates the machine's movements. It calculates the tool's position and speed at all times.

Drive Motors: Drive motors, often servos or steppers, receive signals from the processor to move the machine's various parts along the X, Y, and Z axes. They ensure precise positioning and movement.

Axis Components: Linear guides, lead screws, and ball screws are key components of the X, Y, and Z axes. These components control the movement and positioning of the tool and workpiece.

Tool Spindle: The tool spindle holds the cutting or shaping tool. It rotates the tool at the programmed speed and direction, ensuring that the workpiece is machined accurately.

Coolant System: The coolant system maintains the cutting tool and workpiece at the optimal temperature during machining. This prevents overheating and extends tool life.

Worktable or Bed: The worktable or bed secures the workpiece in place. It can move along the axes to position the workpiece accurately for machining.

Tool Changer: For CNC machines with multiple tools, an automated tool changer switches tools as needed during machining, reducing downtime and increasing efficiency.

Feedback Systems: Feedback systems, like encoders or resolvers, provide real-time information about the machine's position and status. They help maintain accuracy and enable adjustments as necessary.

Hydraulic or Pneumatic Systems: Some CNC machines use hydraulic or pneumatic systems for clamping, lifting, or other auxiliary functions. These systems support the overall machining process.

Coolant and Lubrication Systems: These systems ensure that the machine's moving parts and the tool remain properly lubricated, reducing friction and wear during operation.

Enclosure and Safety Systems: The enclosure contains debris and protects operators from moving parts. Safety systems, including emergency stops, ensure the well-being of operators and prevent accidents.