|

Ningbo Yinzhou Hongyong Machinery Factory

|

Gold Index: 31624

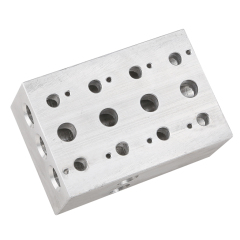

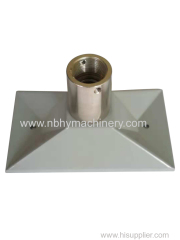

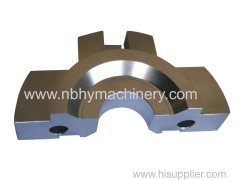

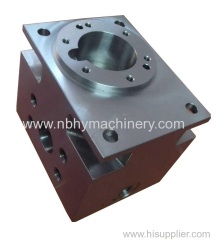

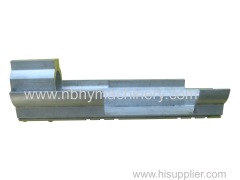

part of the machine

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

A part of a machine can refer to any component or component of the machine, whether it is a simple household appliance or a complex industrial machine

Product Attribute

Packing:Delivery Date:Supply:Material:Weight:Machining:

| Wooden Case/Pallet | 30-35days after the... |

| Drawing Design or OEM | Stainless Steel |

| 0.92kgs | Machining Center |

Product Description

| 1 | Business Type: | OEM& ODM Manufacturer |

| 2 | Products Range: | Auto /Moto Parts, Machinery Parts, Hardware Accessories, Furniture Hardware etc |

| 3 | Materials: | Aluminum: AL6061, AL6082, AL7075, AL5052, etc |

| Steel: S355ML, S420ML, P20, SKD11, SKD61, SKH9, SKH51, S45C, etc | ||

| Iron: 1C45, Y15, C1211, SUM2212L14, 1215, etc | ||

| Stainless steel: SUS304, SUS303, SU316L, SUS440C, etc | ||

| 4 | Machining: | cleaning, turning, milling, drilling, grinding ,CNC shearing,laser cutting, welding etc |

| 5 | Surface Treatment: | Polishing, Deburring, Chrom Plate, Ni Plated, Zine plated, Silver platinng |

| Clear anodizing, Anodizing black, Carburizing Nitriding, Heat Treatment, etc | ||

| 6 | Testing Equipment: | Hexagon CMM, TESA Height Gauge, Projector, Micrometer, etc |

| 7 | QC System: | 100% Inspection before shipment |

| 8 | Payment Term: | T/T, L/C, D/P |

| 9 | Trade Terms: | FOB, CIF |

| 10 | Delivery Time: | 20-30Days(According to The Order) |

| 11 | Our Advantages: | Reliable Quality |

| Competitive Price | ||

| High precision, high quality, tight tolerance | ||

| Continuous Improvement | ||

| On-Time Delivery | ||

| Customer Satisfaction | ||

| Excellent After-Sales Service |

Tags: part of the machine

How do machine components work together during the manufacturing process?

Machine components work together in a coordinated manner during the manufacturing process to ensure the efficient production of goods. Here's how these components collaborate:

Input and Programming: The manufacturing process begins with input from a human operator or a computer system. Instructions are programmed, specifying the desired product's design, dimensions, and production parameters.

Machine Control: The programmed instructions are sent to the machine's control system, which interprets the commands and coordinates the various components.

Drive Mechanisms: Drive mechanisms, such as electric motors or hydraulics, provide power to move the machine's components. These mechanisms ensure that parts of the machine move as intended.

Tooling and Workholding: Tooling includes cutting tools, molds, or dies, while workholding devices secure the raw material or workpiece in place. These components play a central role in shaping and transforming the material.

Workpiece Movement: Depending on the machine's design, the workpiece may move along multiple axes or rotate as needed to reach the cutting or shaping tools.

Guidance Systems: Linear guides and ball screws maintain the alignment and stability of moving parts, ensuring accuracy during machining or production.

Temperature Control: Some manufacturing processes require precise temperature control. Cooling or heating elements help maintain the material and tooling at the right temperatures for processing.

Feedback Systems: Encoders, sensors, and detectors provide real-time data on the machine's performance and the quality of the product. This feedback helps the control system make adjustments as necessary.

Safety Mechanisms: Safety components, such as emergency stops and interlocks, ensure that the machine stops in the event of a problem or if an operator's safety is at risk.

Quality Control: Inspection and measurement systems can be integrated into the machine to monitor product quality and dimensions during production.

Material Handling: Material handling components, such as conveyors and robotic arms, transport raw materials or finished products between various stages of the manufacturing process.

Automation and Robotics: Automated systems and robots can handle repetitive tasks and perform complex operations with precision and speed.

Control Software: Control software manages the execution of the programmed instructions and the coordination of the machine's components.

Operator Interface: The operator interacts with the machine through an interface, making adjustments, monitoring progress, and ensuring safe and efficient operation.

Power Supply and Energy Management: Power sources provide the necessary energy to run the machine, and energy management systems optimize usage for efficiency.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Ningbo Yinzhou Hongyong Machinery Factory [China (Mainland)]

Business Type:Manufacturer

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (500)

- CNC Maching Parts (122)

- Casting Parts (137)

- Stamping Parts (36)

- Forging Parts (36)

- Other products (168)

- Others (1)