|

Ningbo Yinzhou Hongyong Machinery Factory

|

custom machine hongyong machinery

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

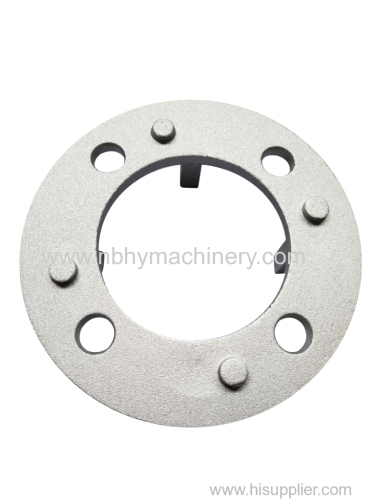

CNC Precision Machining for Transportation &Industrial Applications SUS 304 Csp Punching Part

CNC Precision Machining for Transportation &Industrial Applications SUS 304 Csp Punching Parts

CNC lathe processing technology is more accurate.Each equipment has professional worker to operate.

100% responsibility for quality problems & Fast delivery

Packing according to customer requirements

30% deposit ,70% payment aganist B/L

made in China

CNC machining parts is a computer numerical control machining technology that has the characteristics of high precision, high efficiency, and repeatability, and is widely used in various industries. By programming and controlling machine tools, CNC machining parts can process various materials and complex shaped components, providing strong support for product design and manufacturing. At the same time, CNC machining parts can also improve production efficiency and reduce production costs, making them an indispensable and important link in modern manufacturing.

CNC machining parts is a widely used machining method in mechanical equipment manufacturing, which achieves precise machining of materials through computer programs and CNC machine tools. It has the advantages of high precision, high efficiency, and repeatability. This processing method can meet the processing needs of different components, including various materials and complex shapes, and is therefore widely used in various industries.

custom machine--A Guide to Frequently Asked Questions

1.How can CNC machining parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

2.How to ensure the dimensional accuracy of custom machine to meet assembly and splicing requirements?

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

3.How can CNC machining parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

3. Reasonable selection of tool paths can improve machining efficiency and accuracy. When selecting, comprehensive consideration should be given to processing needs and material characteristics.

4. During the machining process, the stability of the workpiece should be ensured to prevent factors such as vibration from affecting the machining effect.

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

4.Are CNC machining parts suitable for high or low temperature environments, such as aerospace or polar applications?

yes.In the field of aerospace, CNC lathes can process various complex components and parts

5.What are the trends in digitization and automation of CNC machining parts to improve production efficiency and quality control?

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

6.What is the corrosion resistance of CNC machining parts and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

7.How does the manufacturing process and process of CNC machining parts affect their quality and accuracy?

The manufacturing process and process of CNC machining parts affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

8.How can CNC machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

9.What are the common materials used for custom machine?

Titanium, Aluminum, Stainless Steel, Copper/Brass, Iron, any types of alloy