|

Ningbo Yinzhou Hongyong Machinery Factory

|

aluminum alloy cnc machining parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Ningbo Yinzhou Hongyong Machinery Factory was located in Ningbo China, a port city. We are a professional machine parts manufacturer. We are specialized in many kinds of machining parts, including precision machining parts,casting parts,metal hardware,CNC parts,etc. Material covers Chrome steel,Cold rolled sheet,Nylon,Iron,Carbon steel,Aluminum,Steel Alloys,Steel,Plastic,Brass,Stainless Steel,any types of alloy,etc.

The appropriate price and high-quality service are our original intention. We have a professional QC team, which is a strong support for our pursuit of quality. Continually improving the quality which pursue customers' satisfaction is the most important task for us.

aluminum alloy cnc machining parts:Custom Turning Machining Spare Part CNC Machined Parts

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

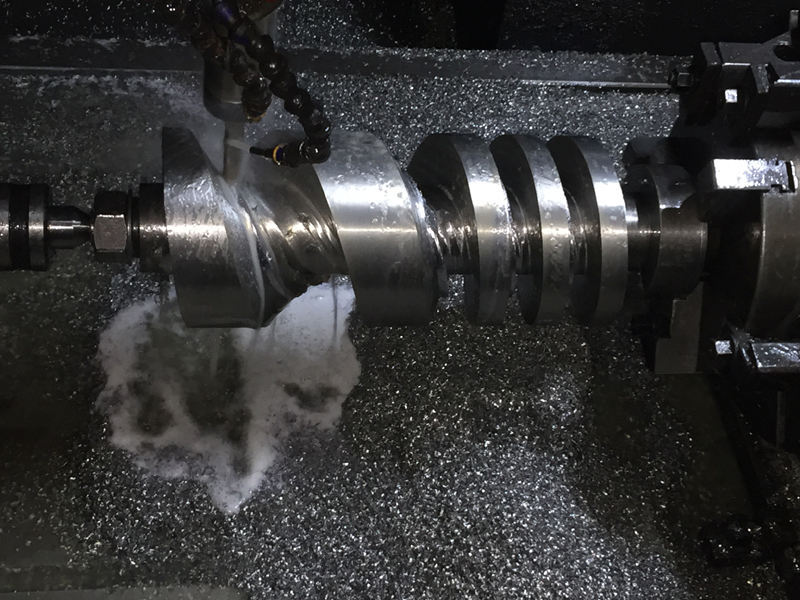

This is our workshop and equipment

aluminum alloy cnc machining parts---FAQs Guide

1.What is the machining accuracy and repeatability of aluminum alloy cnc machining parts to achieve assembly and interchangeability?

2.As a aluminum alloy cnc machining parts manufacturer,OEM/ODM customer's logo printed is available?

3.Is aluminum alloy cnc machining parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

4.As a aluminum alloy cnc machining parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

5.What are the product skill training options?

6.Is aluminum alloy cnc machining parts suitable for manufacturing parts with high safety and food labeling requirements?

7.Are there aluminum alloy cnc machining parts suitable for parts with special shapes or complex structures?

8.Are aluminum alloy cnc machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

9.What is the relationship between the cost and performance of aluminum alloy cnc machining parts, and how to conduct a cost-benefit analysis?

10.How can aluminum alloy cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

11.What is the cleaning and maintenance process for aluminum alloy cnc machining parts to ensure equipment hygiene and performance?

12.How about the maintainability and spare parts supply of aluminum alloy cnc machining parts?

13.About aluminum alloy cnc machining parts,can I get a quote without drawings?

14.How do aluminum alloy cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

15.What is the data collection and monitoring function of aluminum alloy cnc machining parts to improve production traceability and control?

16.How does the selection of machine tools and cutting tools for aluminum alloy cnc machining parts affect machining speed and quality?

1.What is the machining accuracy and repeatability of aluminum alloy cnc machining parts to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

2.As a aluminum alloy cnc machining parts manufacturer,OEM/ODM customer's logo printed is available?

YES, OEM/ODM, customer's logo welcomed.

3.Is aluminum alloy cnc machining parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, aluminum alloy cnc machining parts are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

4.As a aluminum alloy cnc machining parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

Yes,we can.

5.What are the product skill training options?

Our training options include:

1. Basic knowledge of CNC machining

2. CNC programming technology

3. Machining process and fixture design

4. Operating skills of CNC machining centers

5. Troubleshooting and maintenance

6. Safety operation and quality control

7. Application cases and practical operations

6.Is aluminum alloy cnc machining parts suitable for manufacturing parts with high safety and food labeling requirements?

Yes, aluminum alloy cnc machining parts can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

7.Are there aluminum alloy cnc machining parts suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

8.Are aluminum alloy cnc machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, aluminum alloy cnc machining parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

9.What is the relationship between the cost and performance of aluminum alloy cnc machining parts, and how to conduct a cost-benefit analysis?

The processing cost varies with the type of machine, and the time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost. The time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost, The processing cost will also increase with the complexity of CNC machining parts, and material cost is also essential when calculating CNC machining costs

10.How can aluminum alloy cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the aluminum alloy cnc machining parts industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

11.What is the cleaning and maintenance process for aluminum alloy cnc machining parts to ensure equipment hygiene and performance?

We are centered on customers and always pay attention to customers' needs for aluminum alloy cnc machining parts products.

1.Strictly follow the operating rules

2.Preventing overheating of CNC devices

3.Regularly monitor the grid voltage of CNC devices

4.Prevent dust from entering the CNC device 4Regular inspection and replacement of storage batteries.

5.Maintenance of CNC systems when not in use for a long time

12.How about the maintainability and spare parts supply of aluminum alloy cnc machining parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

13.About aluminum alloy cnc machining parts,can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

14.How do aluminum alloy cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

aluminum alloy cnc machining parts use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

15.What is the data collection and monitoring function of aluminum alloy cnc machining parts to improve production traceability and control?

We focus on providing high aluminum alloy cnc machining parts quality products and services.

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

16.How does the selection of machine tools and cutting tools for aluminum alloy cnc machining parts affect machining speed and quality?

We have been working hard to improve service quality and meet customer needs.

1.Ensure the selection of appropriate cutting tools, and determine the type and specifications of the cutting tools based on the processing materials and requirements. Regularly inspect and replace severely worn tools to maintain their sharpness and work efficiency

2.Ensure that cutting parameters (such as cutting speed, feed rate, and cutting depth) are set reasonably to adapt to different machining tasks and materials

3.The fixation of the tool and the clamping state of the workpiece also have an impact on the tool speed

4.Regular maintenance and upkeep of CNC machine tools is also crucial for adjusting tool speed