|

Ningbo Yinzhou Hongyong Machinery Factory

|

big cnc machining parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery is a professional OEM Injection Molding & Metal Fabrication factory located in Ningbo,CHINA and specialize in this field. Our main business is CNC Machining, plastic injection molding,and stamping parts. We now have sophisticated CNC machining center, Polishing machine,Assembly line,Milling machine,Hydraulic shearer,Hydraulic bending machine,Laser cutting machine and other equipments.

Our dedicated test and inspection department features the following equipment:Video measurement (profile projector),Granite Surface Plate,Caliper digital,High gauge,Indicator,Pin gauge,Block gauge,Thread gauge,etc.It is a strong support for our pursuit of quality. Our main export markets: Europe,Oceania,Asia,Grenada,Marshall Islands,Congo, Democratic Republic of the,Saudi Arabia,Ethiopia,etc. And the payment terms is T/T, L/C, D/P.

big cnc machining parts:Custom Turning Machining Spare Part CNC Machined Parts

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

T/T 30% prepaid and balance paid before shipment for the first batch order

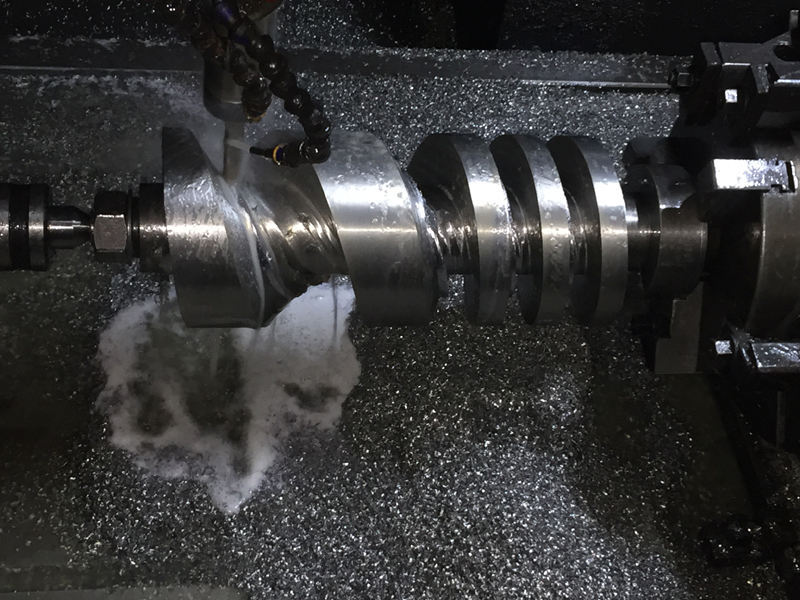

This is our workshop and equipment

big cnc machining parts---FAQs Guide

1.What is the relationship between the cost and performance of big cnc machining parts, and how to conduct a cost-benefit analysis?

2.What is the research and development capability of the factory?

3.How does the manufacturing process and process of big cnc machining parts affect their quality and accuracy?

4.Are there big cnc machining parts suitable for parts with special shapes or complex structures?

5.About big cnc machining parts,How about the lead time?

6.Are big cnc machining parts suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

7.How can big cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

8.How do big cnc machining parts manage supply chain and inventory to ensure timely delivery and production planning?

9.What is the role of CNC machining parts in the manufacturing industry?

10.What are the advantages of big cnc machining parts?

11.How about the maintainability and spare parts supply of big cnc machining parts?

12.How do big cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

13.Are big cnc machining parts subjected to heat treatment or surface treatment to enhance their performance?

14.Is big cnc machining parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

1.What is the relationship between the cost and performance of big cnc machining parts, and how to conduct a cost-benefit analysis?

The processing cost varies with the type of machine, and the time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost. The time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost, The processing cost will also increase with the complexity of CNC machining parts, and material cost is also essential when calculating CNC machining costs

2.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

3.How does the manufacturing process and process of big cnc machining parts affect their quality and accuracy?

The manufacturing process and process of big cnc machining parts affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

4.Are there big cnc machining parts suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

5.About big cnc machining parts,How about the lead time?

It depends on quantity, generally around 20-30 days after receipt of deposit (may vary depending on specific items and item quantities)

6.Are big cnc machining parts suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

Yes, big cnc machining parts can be suitable for safety critical applications with high precision and reliability requirements. CNC machining is a highly accurate and repeatable process that can produce parts with tight tolerances and high levels of precision. CNC machining can also be used to produce parts with complex geometries and intricate details, making it suitable for a wide range of applications.

7.How can big cnc machining parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the big cnc machining parts industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

8.How do big cnc machining parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for big cnc machining parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

9.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency

10.What are the advantages of big cnc machining parts?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced big cnc machining parts products.

1. Highly precise

2. High efficiency

3. Strong flexibility

4. Simple operation

5. Stable quality

6. High productivity

7. Wide processing range

8. Cost saving

9. Reliable and stable

11.How about the maintainability and spare parts supply of big cnc machining parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

12.How do big cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

big cnc machining parts use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

13.Are big cnc machining parts subjected to heat treatment or surface treatment to enhance their performance?

Yes, big cnc machining parts can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

14.Is big cnc machining parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, big cnc machining parts are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.