|

Ningbo Yinzhou Hongyong Machinery Factory

|

china aluminium cnc machining part

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery Factory was located in Ningbo China, a port city. We are a professional machine parts manufacturer. We are specialized in many kinds of machining parts, including precision machining parts,metal hardware,CNC parts,casting parts,etc. Material covers Steel Alloys,Cold rolled sheet,Plastic,Iron,Titanium,Carbon steel,Copper,Alloy,Nylon,Aluminum,Steel,Stainless Steel,etc.

The appropriate price and high-quality service are our original intention. We have a professional QC team, which is a strong support for our pursuit of quality. Continually improving the quality which pursue customers' satisfaction is the most important task for us.

china aluminium cnc machining part:

Machine: 3/4/5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

30% deposit ,70% payment aganist B/L

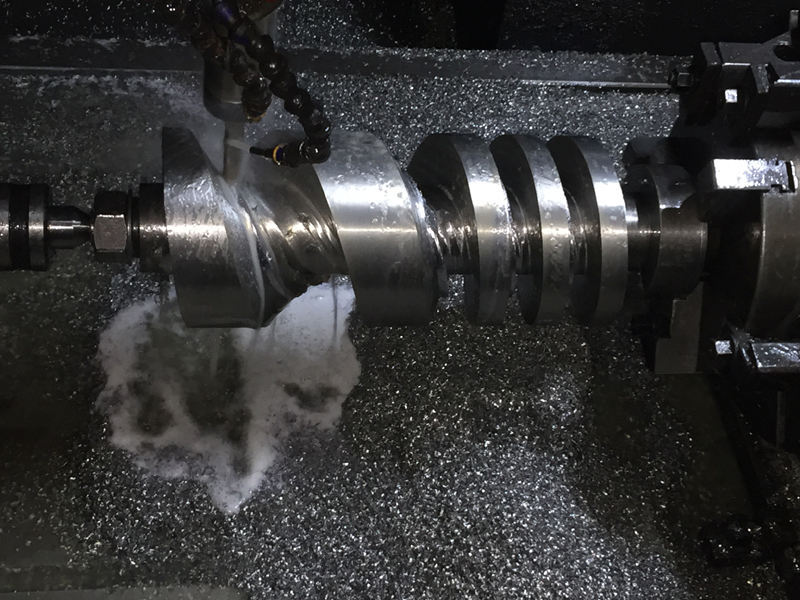

This is our workshop and equipment

china aluminium cnc machining part---FAQs Guide

1.How to ensure the dimensional accuracy of china aluminium cnc machining part to meet assembly and splicing requirements?

2.Is china aluminium cnc machining part suitable for manufacturing parts with high safety and food labeling requirements?

3.What is the data collection and monitoring function of china aluminium cnc machining part to improve production traceability and control?

4.Are china aluminium cnc machining part suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

5.What is the research and development capability of the factory?

6.Are china aluminium cnc machining part suitable for high or low temperature environments, such as aerospace or polar applications?

7.How can china aluminium cnc machining part cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

8.What are the product skill training options?

9.What are the trends in digitization and automation of china aluminium cnc machining part to improve production efficiency and quality control?

10.How do china aluminium cnc machining part manage supply chain and inventory to ensure timely delivery and production planning?

11.Can the size and shape of china aluminium cnc machining part be customized according to needs?

12.Is china aluminium cnc machining part suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

13.About china aluminium cnc machining part,How about the lead time?

14.What are the advantages of china aluminium cnc machining part?

15.As a china aluminium cnc machining part manufacturer,what is the material?

1.How to ensure the dimensional accuracy of china aluminium cnc machining part to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

2.Is china aluminium cnc machining part suitable for manufacturing parts with high safety and food labeling requirements?

Yes, china aluminium cnc machining part can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

3.What is the data collection and monitoring function of china aluminium cnc machining part to improve production traceability and control?

We focus on providing high china aluminium cnc machining part quality products and services.

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

4.Are china aluminium cnc machining part suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, china aluminium cnc machining part can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

5.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

6.Are china aluminium cnc machining part suitable for high or low temperature environments, such as aerospace or polar applications?

yes.In the field of aerospace, CNC lathes can process various complex components and parts

7.How can china aluminium cnc machining part cope with applications in high vibration and impact environments, such as transportation equipment or vibrating screens?

Reduce the cutting force to the minimum;It is to enhance the static rigidity of the tool system or fixture with the workpiece as much as possible

8.What are the product skill training options?

Our training options include:

1. Basic knowledge of CNC machining

2. CNC programming technology

3. Machining process and fixture design

4. Operating skills of CNC machining centers

5. Troubleshooting and maintenance

6. Safety operation and quality control

7. Application cases and practical operations

9.What are the trends in digitization and automation of china aluminium cnc machining part to improve production efficiency and quality control?

We are a professional china aluminium cnc machining part company dedicated to providing high quality products and services.

1.Improvement in accuracy and efficiency

2.The development of intelligence

3.Transformation and popularization

4.Enhance connectivity

10.How do china aluminium cnc machining part manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for china aluminium cnc machining part products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

11.Can the size and shape of china aluminium cnc machining part be customized according to needs?

Yes, china aluminium cnc machining part can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

12.Is china aluminium cnc machining part suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, china aluminium cnc machining part are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

13.About china aluminium cnc machining part,How about the lead time?

It depends on quantity, generally around 20-30 days after receipt of deposit (may vary depending on specific items and item quantities)

14.What are the advantages of china aluminium cnc machining part?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced china aluminium cnc machining part products.

1. Highly precise

2. High efficiency

3. Strong flexibility

4. Simple operation

5. Stable quality

6. High productivity

7. Wide processing range

8. Cost saving

9. Reliable and stable

15.As a china aluminium cnc machining part manufacturer,what is the material?

Plastics we can manufacture are ABS, PC, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.