|

Ningbo Yinzhou Hongyong Machinery Factory

|

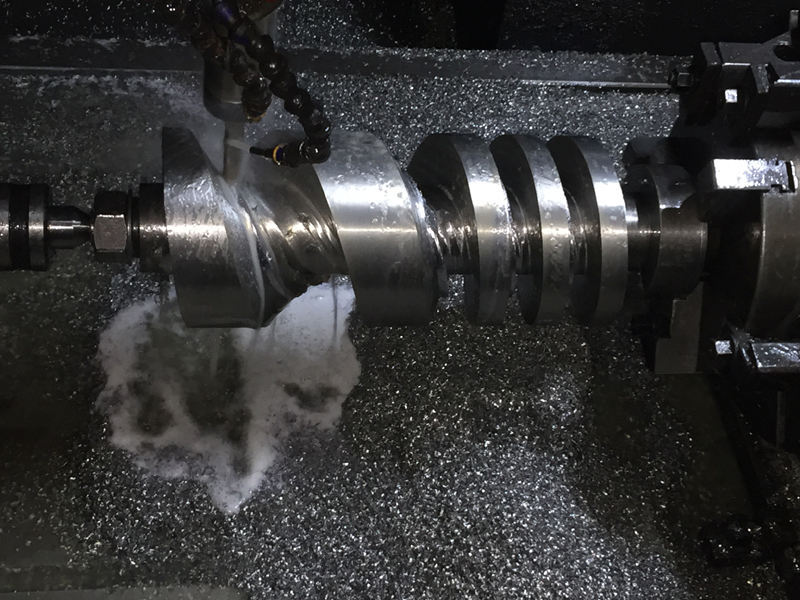

3d printed cnc machine parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

OEM Precision Metal CNC Machinery Machining Parts for Sewing Machine Shop

Hongyong Machinery was located in Ningbo China, a port city. We are a professional machine parts manufacturer. We are specialized in many kinds of machining parts, including forging parts,CNC parts,precision machining parts,metal hardware,etc. Material covers Carbon steel,Chrome steel,Nylon,Alloy,Plastic,Steel Alloys,Titanium,Aluminum,Brass,Copper,Steel,Cold rolled sheet,etc.

The appropriate price and high-quality service are our original intention. We have a professional QC team, which is a strong support for our pursuit of quality. Continually improving the quality which pursue customers' satisfaction is the most important task for us.

3d printed cnc machine parts technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

T/T 30% prepaid and balance paid before shipment for the first batch order

This is our Qualifications & Authorization

3d printed cnc machine parts---FAQs Guide

1.How about the maintainability and spare parts supply of 3d printed cnc machine parts?

2.Is 3d printed cnc machine parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

3.What is the corrosion resistance of 3d printed cnc machine parts and is it suitable for applications with corrosive media?

4.How to ensure that the surface finish and quality of 3d printed cnc machine parts meet the specification requirements?

5.Are 3d printed cnc machine parts suitable for high or low temperature environments, such as aerospace or polar applications?

6.How can 3d printed cnc machine parts control material waste and improve resource utilization to reduce costs?

7.How can 3d printed cnc machine parts respond to voltage and power standards in different regions and countries?

8.As a 3d printed cnc machine parts manufacturer,what is the material?

9.How can 3d printed cnc machine parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

10.How can 3d printed cnc machine parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

11.What is the role of CNC machining parts in the manufacturing industry?

1.How about the maintainability and spare parts supply of 3d printed cnc machine parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

2.Is 3d printed cnc machine parts suitable for manufacturing parts required by special industry standards and regulations, such as aerospace?

Yes, 3d printed cnc machine parts are suitable for manufacturing parts required by special industry standards and regulations, such as aerospace. CNC machining is a precise and accurate process that can produce parts with tight tolerances and complex geometries. It is also capable of producing parts with high levels of repeatability and consistency, which is essential for parts used in the aerospace industry.

3.What is the corrosion resistance of 3d printed cnc machine parts and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

4.How to ensure that the surface finish and quality of 3d printed cnc machine parts meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for 3d printed cnc machine parts products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

5.Are 3d printed cnc machine parts suitable for high or low temperature environments, such as aerospace or polar applications?

yes.In the field of aerospace, CNC lathes can process various complex components and parts

6.How can 3d printed cnc machine parts control material waste and improve resource utilization to reduce costs?

Our products & services cover a wide range of areas and meet the needs of different fields.

1.Optimize processing technology

2.Select appropriate CNC machine tools and control systems

3.Plan and manage production

4.Reduce material consumption and production costs

5.Using efficient molds and equipment

6.Improve production and management systems

7.How can 3d printed cnc machine parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

8.As a 3d printed cnc machine parts manufacturer,what is the material?

Plastics we can manufacture are ABS, PC, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

9.How can 3d printed cnc machine parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

10.How can 3d printed cnc machine parts cope with the manufacturing of non-standard or complex workpieces, such as reverse engineering or special shapes?

We have established a good reputation and reliable partnerships within the 3d printed cnc machine parts industry.

1.detailed design and modeling of the parts are required

2.Programming is a very important step in the machining process of CNC machine tools

11.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency