|

Ningbo Yinzhou Hongyong Machinery Factory

|

cheap cnc machined plastic parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

As a professional cnc machine parts manufacturer,through years' experience and development , Hongyong Machinery Factory has become one of the biggest CNC machining industry and leading export in China, and build an impressive reputation from our partners and customers. Based on our accurate machining, competitive cost and satisfactory customer service, our products have been exported to many countries.

The mechanical parts we produce include CNC parts,precision machining parts,casting parts,metal hardware,etc. Our processing methods include: Casting,CNC Turning,Grinding,Tapping,Gear cutting,Stamping,Drilling, etc. Surface treatment: heat treatment,Sandblasting,plating,Zinc plating,Powder coating,Chrome plating,hardening,Vacuum plating,polishing,Nickel plating,Ion nitriding,Anodizing,Oxidation, etc.Our dedicated test and inspection department features the following equipment:High gauge,Coordinate measuring machine (CMM),Granite Surface Plate,Video measurement (profile projector),Pin gauge,Caliper digital,Block gauge,Thread gauge,etc.Continually improving the quality which pursue customers' satisfaction is the most important task for us.

cheap cnc machined plastic parts:

Machine: 3/4/5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

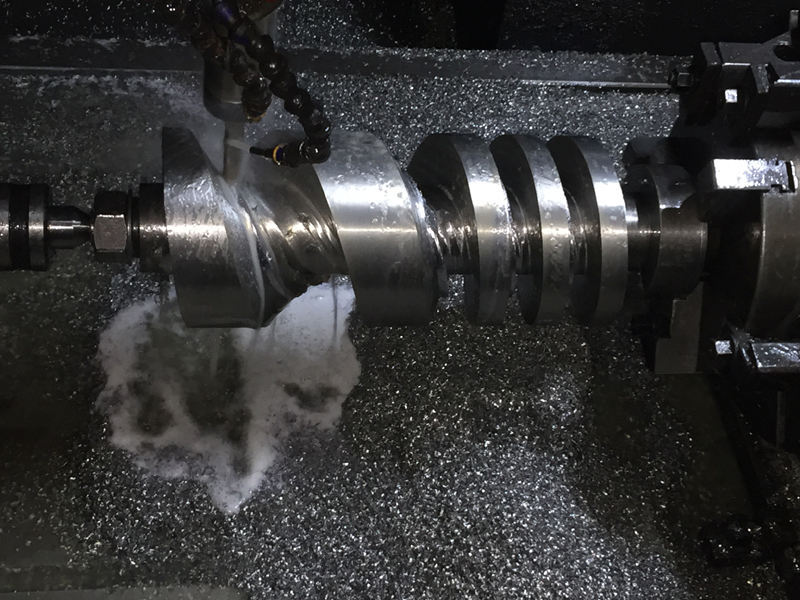

This is our workshop and equipment

cheap cnc machined plastic parts---FAQs Guide

1.How can cheap cnc machined plastic parts control material waste and improve resource utilization to reduce costs?

2.What is the research and development capability of the factory?

3.What is the corrosion resistance of cheap cnc machined plastic parts and is it suitable for applications with corrosive media?

4.What is the accuracy and repeatability of cheap cnc machined plastic parts?

5.How can cheap cnc machined plastic parts respond to voltage and power standards in different regions and countries?

6.Are cheap cnc machined plastic parts subjected to heat treatment or surface treatment to enhance their performance?

7.How to carry out quality control and inspection during the production process of cheap cnc machined plastic parts?

8.What is the cleaning and maintenance process for cheap cnc machined plastic parts to ensure equipment hygiene and performance?

9.How do cheap cnc machined plastic parts manage supply chain and inventory to ensure timely delivery and production planning?

10.About cheap cnc machined plastic parts,Where can I get product&price information?

11.As a cheap cnc machined plastic parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

12.How about the maintainability and spare parts supply of cheap cnc machined plastic parts?

13.How does the manufacturing process and process of cheap cnc machined plastic parts affect their quality and accuracy?

14.What is the production capacity of cheap cnc machined plastic parts, and can they meet the needs of large-scale production?

1.How can cheap cnc machined plastic parts control material waste and improve resource utilization to reduce costs?

Our products & services cover a wide range of areas and meet the needs of different fields.

1.Optimize processing technology

2.Select appropriate CNC machine tools and control systems

3.Plan and manage production

4.Reduce material consumption and production costs

5.Using efficient molds and equipment

6.Improve production and management systems

2.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

3.What is the corrosion resistance of cheap cnc machined plastic parts and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

4.What is the accuracy and repeatability of cheap cnc machined plastic parts?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

5.How can cheap cnc machined plastic parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

6.Are cheap cnc machined plastic parts subjected to heat treatment or surface treatment to enhance their performance?

Yes, cheap cnc machined plastic parts can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

7.How to carry out quality control and inspection during the production process of cheap cnc machined plastic parts?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Control the accuracy of the machine tool

2. Monitor and test tool wear

3. Control the temperature during the machining process

4. Inspect the processed parts

8.What is the cleaning and maintenance process for cheap cnc machined plastic parts to ensure equipment hygiene and performance?

We are centered on customers and always pay attention to customers' needs for cheap cnc machined plastic parts products.

1.Strictly follow the operating rules

2.Preventing overheating of CNC devices

3.Regularly monitor the grid voltage of CNC devices

4.Prevent dust from entering the CNC device 4Regular inspection and replacement of storage batteries.

5.Maintenance of CNC systems when not in use for a long time

9.How do cheap cnc machined plastic parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for cheap cnc machined plastic parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

10.About cheap cnc machined plastic parts,Where can I get product&price information?

Send us e-mail , we will contact you as we receive your mail.

11.As a cheap cnc machined plastic parts manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

Yes,we can.

12.How about the maintainability and spare parts supply of cheap cnc machined plastic parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

13.How does the manufacturing process and process of cheap cnc machined plastic parts affect their quality and accuracy?

The manufacturing process and process of cheap cnc machined plastic parts affect their quality and accuracy in several ways. First, the accuracy of the CNC machining process is dependent on the quality of the raw materials used. If the raw materials are of poor quality, the accuracy of the machined parts will be compromised. Second, the accuracy of the machined parts is also affected by the accuracy of the CNC machine itself. If the machine is not properly calibrated or maintained, the accuracy of the machined parts will be compromised. Finally, the accuracy of the machined parts is also affected by the skill of the operator. If the operator is not experienced or trained properly, the accuracy of the machined parts will be compromised.

14.What is the production capacity of cheap cnc machined plastic parts, and can they meet the needs of large-scale production?

cheap cnc machined plastic parts are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.