|

Ningbo Yinzhou Hongyong Machinery Factory

|

cheap cnc machining parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery specializes in the development, production, and sales of precision metal and plastic parts products. We provide services such as Milling,Gear cutting,Tapping,Grinding,Stamping,Casting,Forging. Since its establishment, our high-tech team and excellent service have enjoyed a high reputation in the domestic market. The materials we use include Plastic,Aluminum,Stainless Steel,Brass,Carbon steel,any types of alloy,Cold rolled sheet,Chrome steel,Steel,Titanium,Copper,Iron, etc. There are surface treatment methods such as Gold plating,Nickel plating,Electroplating,Electrolytic polishing,Titanium nitriding,Sandblasting,Powder coating,Chrome plating,heat treatment,hardening,plating,Ion nitriding,Zinc plating.

We have obtained certifications such as CE, RoHS, GS, ISO9001, etc. Our products are widely used in fields such as Power and energy,medical device industry,oil&gas exploration,machinery accessory,auto and motorcycle accessory,aerospace industry,automation industry. Our precision machinery includes Polishing machine,Punch press 6.3 to 160 T,Welding machine,Assembly line,Laser cutting machine,Hydraulic bending machine and others. Our products have been exported to more than 30 countries, including the United States, South Korea, Russia, and Dominica,Spain,Laos,British Indian Ocean Territory,Guadeloupe,Syria. We always take pride in maintaining a high-quality spirit.

cheap cnc machining parts technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

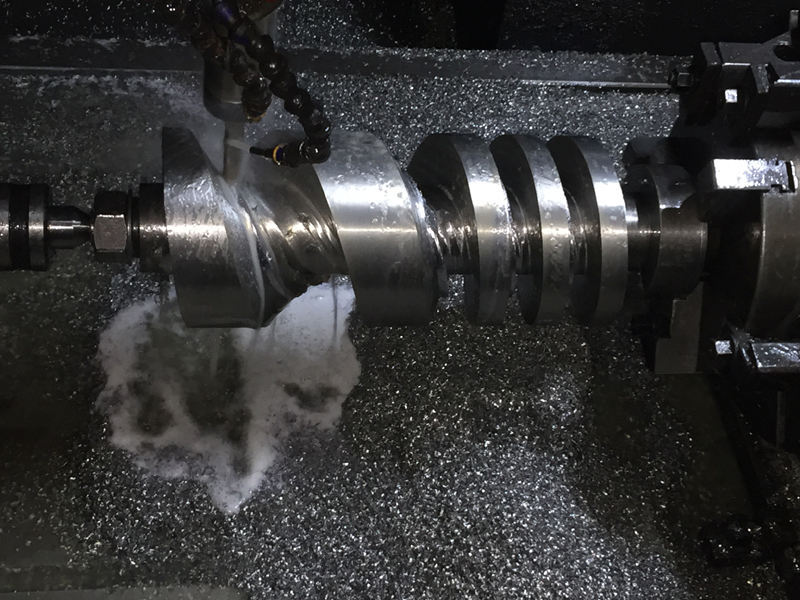

This is our workshop and equipment

cheap cnc machining parts---FAQs Guide

1.Can the size and shape of cheap cnc machining parts be customized according to needs?

2.How can cheap cnc machining parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

3.How can cheap cnc machining parts meet the needs of rapid prototype manufacturing and small batch production?

4.How to ensure the dimensional accuracy of cheap cnc machining parts to meet assembly and splicing requirements?

5.What is the machining accuracy and repeatability of cheap cnc machining parts to achieve assembly and interchangeability?

6.Are there cheap cnc machining parts suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

7.What is the accuracy and repeatability of cheap cnc machining parts?

8.As a cheap cnc machining parts manufacturer,can you make custom parts based on my sample?

9.What are the advantages of cheap cnc machining parts?

10.What is the data collection and monitoring function of cheap cnc machining parts to improve production traceability and control?

11.What is the relationship between the cost and performance of cheap cnc machining parts, and how to conduct a cost-benefit analysis?

12.Are cheap cnc machining parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

13.How can cheap cnc machining parts respond to voltage and power standards in different regions and countries?

14.How can cheap cnc machining parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

15.How do cheap cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

16.How to carry out quality control and inspection during the production process of cheap cnc machining parts?

1.Can the size and shape of cheap cnc machining parts be customized according to needs?

Yes, cheap cnc machining parts can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

2.How can cheap cnc machining parts adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

3.How can cheap cnc machining parts meet the needs of rapid prototype manufacturing and small batch production?

We are centered on customers and always pay attention to customers' needs for cheap cnc machining parts products.

1.When we use CNC for small batch processing, we need to control the drilling of components well

2.When we use CNC for small batch processing, we need to control the turning of components well

3.When we use CNC for small batch processing, we need to control the milling and cutting angles of the components

4.When we use CNC for small batch processing, we need to control the angle of the slotting process of the components

4.How to ensure the dimensional accuracy of cheap cnc machining parts to meet assembly and splicing requirements?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

1. Use high-precision processing equipment and tools.

2. Strictly control the processing process.

3. Use appropriate testing for measurement work.

4. Conduct pre assembly coordination testing and adjustments

5.What is the machining accuracy and repeatability of cheap cnc machining parts to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

6.Are there cheap cnc machining parts suitable for the manufacturing of special precision measurement and calibration equipment, such as microscopes or particle size analyzers?

Yes, cheap cnc machining parts can be used to manufacture special precision measurement and calibration equipment. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape materials into precise shapes and sizes. CNC machining can be used to create parts with tight tolerances and intricate details, making it ideal for precision measurement and calibration equipment.

7.What is the accuracy and repeatability of cheap cnc machining parts?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

8.As a cheap cnc machining parts manufacturer,can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing forproduction.

9.What are the advantages of cheap cnc machining parts?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced cheap cnc machining parts products.

1. Highly precise

2. High efficiency

3. Strong flexibility

4. Simple operation

5. Stable quality

6. High productivity

7. Wide processing range

8. Cost saving

9. Reliable and stable

10.What is the data collection and monitoring function of cheap cnc machining parts to improve production traceability and control?

We focus on providing high cheap cnc machining parts quality products and services.

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

11.What is the relationship between the cost and performance of cheap cnc machining parts, and how to conduct a cost-benefit analysis?

The processing cost varies with the type of machine, and the time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost. The time required for the complete processing of any CNC machining component also plays an important role in the calculation of CNC machining cost. The longer the processing time, the higher the processing cost, The processing cost will also increase with the complexity of CNC machining parts, and material cost is also essential when calculating CNC machining costs

12.Are cheap cnc machining parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, cheap cnc machining parts can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

13.How can cheap cnc machining parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

14.How can cheap cnc machining parts meet the needs of complex geometric shapes and micro dimensions, such as micro mechanical components?

Before preparing the CNC turning process, we need to first confirm the geometric shape and size of the parts to be processed, which requires accurate calculations. For complex shaped parts, CAD software can be used for design and drawing, and then extract the contour and control lines of the parts to be processed. Through these control points, the machining path can be confirmed, and then the CNC machine tool plan and program can be set up

15.How do cheap cnc machining parts handle the extrusion and removal processes of materials to meet design requirements?

cheap cnc machining parts use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.

16.How to carry out quality control and inspection during the production process of cheap cnc machining parts?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Control the accuracy of the machine tool

2. Monitor and test tool wear

3. Control the temperature during the machining process

4. Inspect the processed parts