|

Ningbo Yinzhou Hongyong Machinery Factory

|

cnc machibe Hongyong Machinery

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

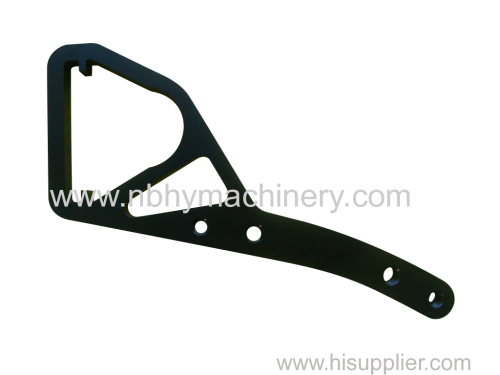

Hight Quality Custom CNC Metal Laser Cutting Machining Parts OEM Manufacturing CNC Turning Maching Parts

Hight Quality Custom CNC Metal Laser Cutting Machining Parts OEM Manufacturing CNC Turning Maching Parts

cnc machibe:

Machine: 3 / 4 /5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

100% responsibility for quality problems & Fast delivery

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

cnc machibe is a computer numerical control machining technology that has the characteristics of high precision, high efficiency, and repeatability, and is widely used in various industries. By programming and controlling machine tools, CNC machining parts can process various materials and complex shaped components, providing strong support for product design and manufacturing. At the same time, CNC machining parts can also improve production efficiency and reduce production costs, making them an indispensable and important link in modern manufacturing.

cnc machibe refer to components manufactured through computer numerical control machining technology. This processing method utilizes computer programs to control mechanical equipment for automated processing, which has the advantages of high precision, high efficiency, and repeatability. CNC machining parts are widely used in various fields, such as automobiles, aerospace, electronic equipment, etc., providing key components for various industries.

Why choose Hongyong Machinery?

1We have decades years of experience in metal parts related products and can customize parts based on customer provided drawings. The appropriate price and high-quality service are our original intention. We have a professional QC team, which is a strong support for our pursuit of quality. Continually improving the quality which pursue customers' satisfaction is the most important task for us.

Hope we will have good cooperation with each other.

Quality Assurance

Our dedicated test and inspection department features the following equipment:

• Coordinate measuring machine (CMM)

• Video measurement (profile projector)

• Pin gauge

• Block gauge

• Thread gauge

• High gauge

• Micrometer ID/OD

CNC machibe--A Guide to Frequently Asked Questions

1.How do CNC machining parts manage supply chain and inventory to ensure timely delivery and production planning?

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

2.How to ensure that the surface finish and quality of CNC machining parts meet the specification requirements?

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

3.Are there CNC machining parts suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

4.Are CNC machining parts suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, CNC machining parts can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

5.Is CNC machining parts suitable for manufacturing parts with high safety and food labeling requirements?

Yes, CNC machining parts can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

6.What is the data collection and monitoring function of CNC machining parts to improve production traceability and control?

1.Collecting various parameters including machine tool feed, spindle speed, temperature, vibration, current, etc., to achieve comprehensive and accurate data collection.

2.Through real-time monitoring and control, abnormal situations during machine tool processing can be detected in a timely manner, and adjustments can be made to improve processing stability and accuracy.

7.Are CNC machining parts suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, CNC machining parts can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

8.What is the research and development capability of the factory?

Secondly, CNC machine tool manufacturers have innovated in control systems. They adopted advanced CNC technology, applying computer, electronic technology, and automatic control technology to machine tool control systems

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.