|

Ningbo Yinzhou Hongyong Machinery Factory

|

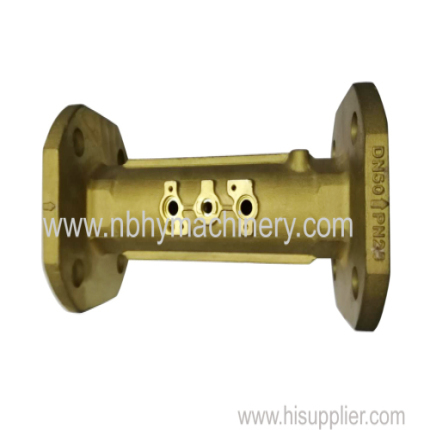

building cnc machine part 3

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery is a mechanical parts production enterprise that has been operating in Ningbo, China for over a decade. We provide the best services in the fields of production and solutions. We specialize in producing and exporting various precision customized metal components, including CNC parts,precision machining parts,metal hardware,casting parts. All of these are provided in the form of single piece, small batch, or series production based on the drawing files provided by the customer.

The product is supplied to industries such as hardware tool,Power and energy,aerospace industry,medical device industry,auto and motorcycle accessory,machinery accessory,automation industry. Our original intention is to offer suitable prices and high-quality service. We have precision machining machinery such as Assembly line,Punch press 6.3 to 160 T,Hydraulic shearer,Welding machine,Polishing machine,Hydraulic bending machine, and our machining methods include Milling,Tapping,Gear cutting,Stamping,Casting,Forging,CNC Turning , etc. We have a professional QC team, which is a strong support for our pursuit of quality.

building cnc machine part 3 technology is more accurate.Each equipment has professional worker to operate.

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton

30% deposit ,70% payment aganist B/L

This is our workshop and equipment

building cnc machine part 3---FAQs Guide

1.How do building cnc machine part 3 manage supply chain and inventory to ensure timely delivery and production planning?

2.Are there building cnc machine part 3 suitable for parts with special shapes or complex structures?

3.Are building cnc machine part 3 suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

4.Is building cnc machine part 3 suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

5.As a building cnc machine part 3 manufacturer,what is the material?

6.How do building cnc machine part 3 handle the cutting and carving processes of materials to meet the requirements of complex parts?

7.Is building cnc machine part 3 suitable for manufacturing parts with high safety and food labeling requirements?

8.Are building cnc machine part 3 subjected to heat treatment or surface treatment to enhance their performance?

9.Are building cnc machine part 3 suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

10.What is the accuracy and repeatability of building cnc machine part 3?

11.Are building cnc machine part 3 suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

1.How do building cnc machine part 3 manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for building cnc machine part 3 products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

2.Are there building cnc machine part 3 suitable for parts with special shapes or complex structures?

Yes, CNC machining is suitable for parts with special shapes or complex structures. CNC machining is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a block of material to create a part with a specific shape and size. CNC machining is ideal for producing parts with complex geometries and intricate details that would be difficult or impossible to produce with traditional manufacturing methods.

3.Are building cnc machine part 3 suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, building cnc machine part 3 can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

4.Is building cnc machine part 3 suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

Yes, building cnc machine part 3 are suitable for applications in high-speed motion and vibration environments. CNC machining parts are designed to be precise and durable, making them ideal for use in high-speed and vibration environments. CNC machining parts are also able to withstand high temperatures and pressures, making them suitable for use in automotive engines and machine tools.

5.As a building cnc machine part 3 manufacturer,what is the material?

Plastics we can manufacture are ABS, PC, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

6.How do building cnc machine part 3 handle the cutting and carving processes of materials to meet the requirements of complex parts?

We operate our building cnc machine part 3 business with integrity and honesty.

1.Cleaning and inspection process

2.Measurement process

3.Adjusting the cutting space of the tool

7.Is building cnc machine part 3 suitable for manufacturing parts with high safety and food labeling requirements?

Yes, building cnc machine part 3 can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

8.Are building cnc machine part 3 subjected to heat treatment or surface treatment to enhance their performance?

Yes, building cnc machine part 3 can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

9.Are building cnc machine part 3 suitable for special surface treatment or coating requirements? Such as wear resistance or corrosion resistance

Yes, building cnc machine part 3 are suitable for special surface treatment or coating requirements. Depending on the application, CNC machined parts can be treated with a variety of coatings, such as anodizing, electroplating, powder coating, and painting. These coatings can provide additional protection against wear and corrosion.

10.What is the accuracy and repeatability of building cnc machine part 3?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

11.Are building cnc machine part 3 suitable for safety critical applications with high precision and reliability requirements, such as automotive braking systems or aviation navigation?

Yes, building cnc machine part 3 can be suitable for safety critical applications with high precision and reliability requirements. CNC machining is a highly accurate and repeatable process that can produce parts with tight tolerances and high levels of precision. CNC machining can also be used to produce parts with complex geometries and intricate details, making it suitable for a wide range of applications.