|

Ningbo Yinzhou Hongyong Machinery Factory

|

china anodizing cnc machined parts

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Ningbo Yinzhou Hongyong Machinery Factory is a mechanical parts production enterprise that has been operating in Ningbo, China for over a decade. We provide the best services in the fields of production and solutions. We specialize in producing and exporting various precision customized metal components, including precision machining parts,metal hardware,casting parts,forging parts. All of these are provided in the form of single piece, small batch, or series production based on the drawing files provided by the customer.

The product is supplied to industries such as machinery accessory,automation industry,auto and motorcycle accessory,home appliance,medical device industry,oil&gas exploration,hardware tool. Our original intention is to offer suitable prices and high-quality service. We have precision machining machinery such as Punch press 6.3 to 160 T,Laser cutting machine,Assembly line,Milling machine,Welding machine,Hydraulic shearer, and our machining methods include Stamping,Forging,Drilling,Casting,CNC Turning,Wire EDM,Tapping , etc. We have a professional QC team, which is a strong support for our pursuit of quality.

china anodizing cnc machined parts:

Customized Design

Sample Order Accepted

Short Delivery time

Competitive Prices

Long time quality Insurance

Professional after-sale services

QC System:100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

30% deposit ,70% payment aganist B/L

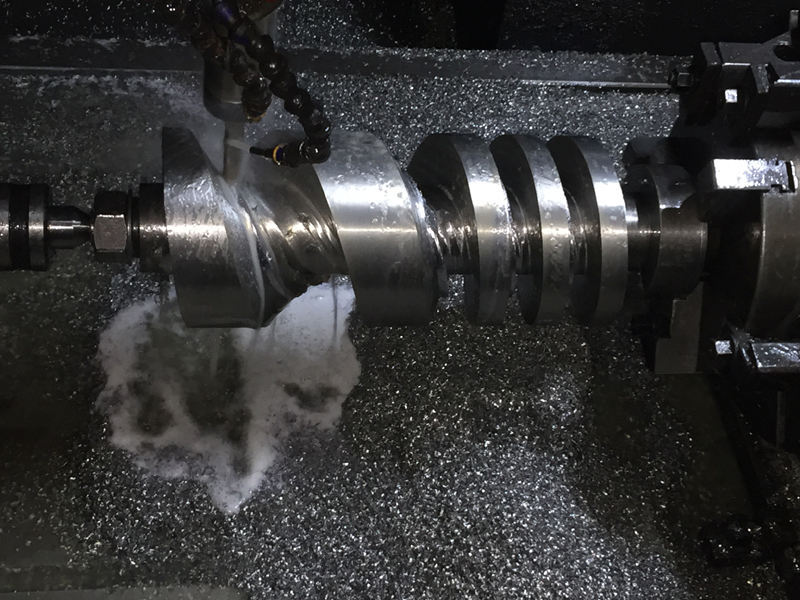

This is our workshop and equipment

china anodizing cnc machined parts---FAQs Guide

1.What is the production capacity of china anodizing cnc machined parts, and can they meet the needs of large-scale production?

2.How about the maintainability and spare parts supply of china anodizing cnc machined parts?

3.What are the product skill training options?

4.As a china anodizing cnc machined parts manufacturer,can you make custom parts based on my sample?

5.How to carry out quality control and inspection during the production process of china anodizing cnc machined parts?

6.Can the size and shape of china anodizing cnc machined parts be customized according to needs?

7.How can china anodizing cnc machined parts respond to voltage and power standards in different regions and countries?

8.How to ensure that the surface finish and quality of china anodizing cnc machined parts meet the specification requirements?

9.What is the cleaning and maintenance process for china anodizing cnc machined parts to ensure equipment hygiene and performance?

10.How do china anodizing cnc machined parts manage supply chain and inventory to ensure timely delivery and production planning?

11.What is the machining accuracy and repeatability of china anodizing cnc machined parts to achieve assembly and interchangeability?

12.How can china anodizing cnc machined parts meet the needs of rapid prototype manufacturing and small batch production?

1.What is the production capacity of china anodizing cnc machined parts, and can they meet the needs of large-scale production?

china anodizing cnc machined parts are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

2.How about the maintainability and spare parts supply of china anodizing cnc machined parts?

When the CNC system is not in use for a long time, the maintenance work should pay attention to the following two aspects:

1.the CNC system should be regularly powered on and running idle, so that the heat from the electronic and electrical components of the CNC system can be used to dissipate the moisture inside the CNC cabinet

2.The normal supply of spare parts is a guarantee measure to ensure the normal and uninterrupted operation of the system. Our company will provide spare parts for auxiliary equipment during the warranty period and random spare parts during equipment installation and debugging

3.What are the product skill training options?

Our training options include:

1. Basic knowledge of CNC machining

2. CNC programming technology

3. Machining process and fixture design

4. Operating skills of CNC machining centers

5. Troubleshooting and maintenance

6. Safety operation and quality control

7. Application cases and practical operations

4.As a china anodizing cnc machined parts manufacturer,can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing forproduction.

5.How to carry out quality control and inspection during the production process of china anodizing cnc machined parts?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Control the accuracy of the machine tool

2. Monitor and test tool wear

3. Control the temperature during the machining process

4. Inspect the processed parts

6.Can the size and shape of china anodizing cnc machined parts be customized according to needs?

Yes, china anodizing cnc machined parts can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

7.How can china anodizing cnc machined parts respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

8.How to ensure that the surface finish and quality of china anodizing cnc machined parts meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for china anodizing cnc machined parts products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

9.What is the cleaning and maintenance process for china anodizing cnc machined parts to ensure equipment hygiene and performance?

We are centered on customers and always pay attention to customers' needs for china anodizing cnc machined parts products.

1.Strictly follow the operating rules

2.Preventing overheating of CNC devices

3.Regularly monitor the grid voltage of CNC devices

4.Prevent dust from entering the CNC device 4Regular inspection and replacement of storage batteries.

5.Maintenance of CNC systems when not in use for a long time

10.How do china anodizing cnc machined parts manage supply chain and inventory to ensure timely delivery and production planning?

We are centered on customers and always pay attention to customers' needs for china anodizing cnc machined parts products.

1. Specify the warehousing standards for components

2. Warehousing of components

3. Review of component delivery notes

4. Quality inspection and acceptance

11.What is the machining accuracy and repeatability of china anodizing cnc machined parts to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

12.How can china anodizing cnc machined parts meet the needs of rapid prototype manufacturing and small batch production?

We are centered on customers and always pay attention to customers' needs for china anodizing cnc machined parts products.

1.When we use CNC for small batch processing, we need to control the drilling of components well

2.When we use CNC for small batch processing, we need to control the turning of components well

3.When we use CNC for small batch processing, we need to control the milling and cutting angles of the components

4.When we use CNC for small batch processing, we need to control the angle of the slotting process of the components