|

Ningbo Yinzhou Hongyong Machinery Factory

|

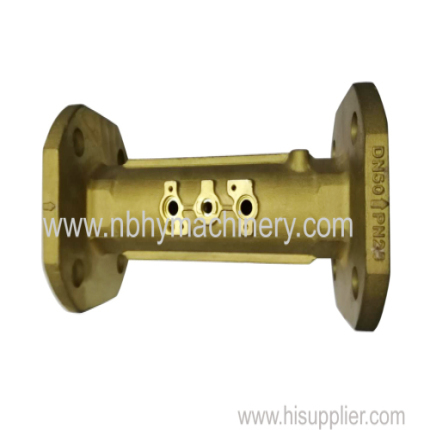

brass parts cnc machining

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery Factory is located in Ningbo City, adjacent to Ningbo Port, and is a professional enterprise that produces precision machining parts,metal hardware,CNC parts,casting parts. We have over ten years of experience in metal parts related products. We can produce customized parts using our equipment based on customer drawings or samples. Our products sell well in markets such as North America, Germany, and Guinea-Bissau,Thailand,Slovenia,Kenya,Nigeria.

We have won the trust of domestic and foreign customers with high quality, on-time delivery, and competitive prices. Our materials include Brass,Stainless Steel,any types of alloy,Plastic,Titanium,Alloy,Nylon,Copper,Aluminum,Steel Alloys,Carbon steel,Iron, etc. Our surface treatment methods include heat treatment,Vacuum plating,Oxidation,Nickel plating,plating,Passivation,Anodizing,Ion nitriding,polishing,hardening,Chrome plating,Electroplating, etc. Our specialized testing and inspection department has the following equipment:Caliper digital,Granite Surface Plate,Micrometer ID/OD,High gauge,Indicator,Pin gauge,Video measurement (profile projector),Coordinate measuring machine (CMM), etc. We have passed certifications such as CE, RoHS, GS, ISO9001. These are powerful supports for our pursuit of quality.

brass parts cnc machining:

Machine: 3/4/5 axis CNC Machining Center

Roughness: Ra0.2-Ra3.2

Tolerance: 0.005~0.05mm or refer to drawings strictly

Main Process: Turning / Milling

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

This is our workshop and equipment

brass parts cnc machining---FAQs Guide

1.Are brass parts cnc machining subjected to heat treatment or surface treatment to enhance their performance?

2.Are brass parts cnc machining suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

3.What is the role of CNC machining parts in the manufacturing industry?

4.How to carry out quality control and inspection during the production process of brass parts cnc machining?

5.How can brass parts cnc machining control material waste and improve resource utilization to reduce costs?

6.What is the corrosion resistance of brass parts cnc machining and is it suitable for applications with corrosive media?

7.Can the size and shape of brass parts cnc machining be customized according to needs?

8.How to ensure that the surface finish and quality of brass parts cnc machining meet the specification requirements?

9.How does the selection of machine tools and cutting tools for brass parts cnc machining affect machining speed and quality?

10.Are brass parts cnc machining suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

11.Is brass parts cnc machining suitable for manufacturing parts with high safety and food labeling requirements?

12.What is the accuracy and repeatability of brass parts cnc machining?

1.Are brass parts cnc machining subjected to heat treatment or surface treatment to enhance their performance?

Yes, brass parts cnc machining can be subjected to heat treatment or surface treatment to enhance their performance. Heat treatment is used to alter the physical and sometimes chemical properties of a material, while surface treatment is used to improve the appearance and/or corrosion resistance of a material.

2.Are brass parts cnc machining suitable for applications under high temperature and pressure conditions, such as oil field equipment or chemical plants?

Yes, brass parts cnc machining can be suitable for applications under high temperature and pressure conditions. CNC machining parts can be made from a variety of materials, including metals such as stainless steel, aluminum, and titanium, which are all suitable for high temperature and pressure applications. Additionally, CNC machining parts can be designed to meet specific requirements, such as corrosion resistance, strength, and durability.

3.What is the role of CNC machining parts in the manufacturing industry?

Improving machining accuracy and quality,Improve production efficiency and efficiency

4.How to carry out quality control and inspection during the production process of brass parts cnc machining?

Our products & services cover a wide range of areas and meet the needs of different fields.

1. Control the accuracy of the machine tool

2. Monitor and test tool wear

3. Control the temperature during the machining process

4. Inspect the processed parts

5.How can brass parts cnc machining control material waste and improve resource utilization to reduce costs?

Our products & services cover a wide range of areas and meet the needs of different fields.

1.Optimize processing technology

2.Select appropriate CNC machine tools and control systems

3.Plan and manage production

4.Reduce material consumption and production costs

5.Using efficient molds and equipment

6.Improve production and management systems

6.What is the corrosion resistance of brass parts cnc machining and is it suitable for applications with corrosive media?

The ability of metal materials to resist the corrosive damage of surrounding media is called corrosion resistance and it is suitable for applications with corrosive media.

7.Can the size and shape of brass parts cnc machining be customized according to needs?

Yes, brass parts cnc machining can be customized according to the customer's needs. CNC machining can produce parts in a variety of sizes and shapes, including complex geometries. The customer can provide a design or drawing of the desired part, and the CNC machining shop can use the design to create the part.

8.How to ensure that the surface finish and quality of brass parts cnc machining meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for brass parts cnc machining products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

9.How does the selection of machine tools and cutting tools for brass parts cnc machining affect machining speed and quality?

We have been working hard to improve service quality and meet customer needs.

1.Ensure the selection of appropriate cutting tools, and determine the type and specifications of the cutting tools based on the processing materials and requirements. Regularly inspect and replace severely worn tools to maintain their sharpness and work efficiency

2.Ensure that cutting parameters (such as cutting speed, feed rate, and cutting depth) are set reasonably to adapt to different machining tasks and materials

3.The fixation of the tool and the clamping state of the workpiece also have an impact on the tool speed

4.Regular maintenance and upkeep of CNC machine tools is also crucial for adjusting tool speed

10.Are brass parts cnc machining suitable for applications in special environments and climatic conditions, such as in marine or desert areas?

Yes, brass parts cnc machining can be suitable for applications in special environments and climatic conditions. Depending on the material used, CNC machining parts can be designed to be corrosion-resistant, heat-resistant, and/or waterproof. Additionally, CNC machining parts can be designed to be lightweight and durable, making them suitable for use in harsh environments.

11.Is brass parts cnc machining suitable for manufacturing parts with high safety and food labeling requirements?

Yes, brass parts cnc machining can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

12.What is the accuracy and repeatability of brass parts cnc machining?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).