|

Ningbo Yinzhou Hongyong Machinery Factory

|

aircraft parts cnc machining

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hongyong Machinery Factory located in ningbo, is a professional service precision metal and plastic parts manufacturer, we have casting parts,metal h

Hongyong Machinery Factory is a professional OEM Injection Molding & Metal Fabrication factory located in Ningbo,CHINA and specialize in this field. Our main business is CNC Machining, plastic injection molding,and stamping parts. We now have sophisticated CNC machining center, Assembly line,Milling machine,Hydraulic bending machine,Hydraulic shearer,Polishing machine,Punch press 6.3 to 160 T and other equipments.

Our dedicated test and inspection department features the following equipment:Coordinate measuring machine (CMM),Video measurement (profile projector),Block gauge,Pin gauge,Caliper digital,High gauge,Indicator,Micrometer ID/OD,etc.It is a strong support for our pursuit of quality. Our main export markets: America,Oceania,Africa,Laos,Moldova,Bahamas, The,Falkland Islands,Libya,etc. And the payment terms is T/T, L/C, D/P.

aircraft parts cnc machining:

Customized Design

Sample Order Accepted

Short Delivery time

Competitive Prices

Long time quality Insurance

Professional after-sale services

Quality Control System: Incoming inspection, process inspection, finished product inspection, delivery inspection.

Inspection Standard: GB/T 1804-2000(Linear and angular tolerances are not noted), GB/T 1184-1996(No tolerance for shape and position), HB5800-1999(No dimensional tolerance stated), GB/T2828.1-2012(AQL).

Carton box or wood box, or per customers' requirement

T/T 30% prepaid and balance paid before shipment for the first batch order

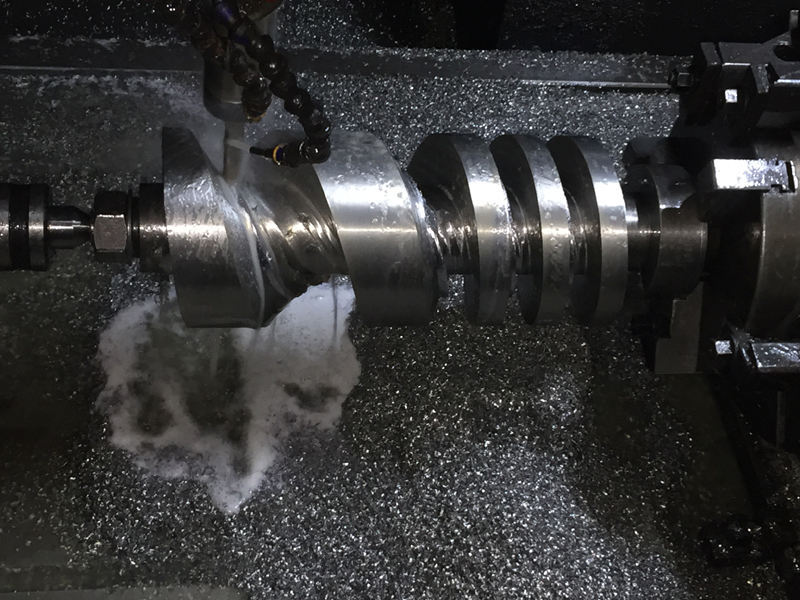

This is our workshop and equipment

aircraft parts cnc machining---FAQs Guide

1.Is aircraft parts cnc machining suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

2.As a aircraft parts cnc machining manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

3.Is aircraft parts cnc machining suitable for manufacturing parts with high safety and food labeling requirements?

4.What is the machining accuracy and repeatability of aircraft parts cnc machining to achieve assembly and interchangeability?

5.How can aircraft parts cnc machining respond to voltage and power standards in different regions and countries?

6.What is the production capacity of aircraft parts cnc machining, and can they meet the needs of large-scale production?

7.As a aircraft parts cnc machining manufacturer,can you make custom parts based on my sample?

8.What is the research and development capability of the factory?

9.How to ensure that the surface finish and quality of aircraft parts cnc machining meet the specification requirements?

10.What is the accuracy and repeatability of aircraft parts cnc machining?

11.How can aircraft parts cnc machining adapt to different hardness and processing requirements of materials, such as steel or plastic?

12.What is the strength and rigidity of aircraft parts cnc machining, suitable for high load applications?

13.How do aircraft parts cnc machining handle the extrusion and removal processes of materials to meet design requirements?

1.Is aircraft parts cnc machining suitable for applications in high-speed motion and vibration environments, such as automotive engines or machine tools?

Yes, aircraft parts cnc machining are suitable for applications in high-speed motion and vibration environments. CNC machining parts are designed to be precise and durable, making them ideal for use in high-speed and vibration environments. CNC machining parts are also able to withstand high temperatures and pressures, making them suitable for use in automotive engines and machine tools.

2.As a aircraft parts cnc machining manufacturer,can you provide one-stop service including of material,processing,finish,assembly etc?

Yes,we can.

3.Is aircraft parts cnc machining suitable for manufacturing parts with high safety and food labeling requirements?

Yes, aircraft parts cnc machining can be used to manufacture parts with high safety and food labeling requirements. CNC machining is a precise and accurate process that can produce parts with tight tolerances and high levels of repeatability. This makes it ideal for producing parts with high safety and food labeling requirements.

4.What is the machining accuracy and repeatability of aircraft parts cnc machining to achieve assembly and interchangeability?

For machine tools with general machining requirements, the repeated positioning accuracy is generally required to be less than or equal to 0.005mm.

5.How can aircraft parts cnc machining respond to voltage and power standards in different regions and countries?

For imported CNC machine tools and equipment, it is necessary to read the accompanying instructions clearly and connect them according to the instructions. Before powering on, it is also necessary to carefully check whether the input voltage and frequency are correct

6.What is the production capacity of aircraft parts cnc machining, and can they meet the needs of large-scale production?

aircraft parts cnc machining are mainly suitable for the following occasions: batch production: CNC lathes are suitable for large-scale and continuous batch production.

7.As a aircraft parts cnc machining manufacturer,can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing forproduction.

8.What is the research and development capability of the factory?

CNC machine tool manufacturers have innovated in the structural design of machine tools. They designed a more compact, stable, and highly rigid structure by analyzing the basic principles of mechanical cutting and the motion characteristics of machine tools. This structure can improve the rigidity and stability of the machine tool, reduce the vibration, noise, and heat generated during high-speed cutting, and thus improve the processing quality and efficiency.

9.How to ensure that the surface finish and quality of aircraft parts cnc machining meet the specification requirements?

We are centered on customers and always pay attention to customers' needs for aircraft parts cnc machining products.

1.selecting appropriate cutting parameters is the key to controlling surface roughness and smoothness

2.the selection and grinding of cutting tools also play an important role in controlling surface roughness and smoothness

10.What is the accuracy and repeatability of aircraft parts cnc machining?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

1.The smaller the difference between the actual position of parts or tools and the standard position (theoretical position, ideal position), the higher the accuracy. It is a prerequisite for ensuring the machining accuracy of parts.

2.The consistency of continuous results obtained by machining a batch of parts under the same conditions (on the same CNC machine tool, with different operating methods and using the same part program).

11.How can aircraft parts cnc machining adapt to different hardness and processing requirements of materials, such as steel or plastic?

During the machining process, attention should always be paid to the wear of the cutting tools, and severely worn cutting tools should be replaced in a timely manner to ensure the machining effect.

When adjusting cutting parameters, comprehensive consideration should be given to factors such as material hardness, cutting depth, and the shape of the workpiece being processed to achieve the best effect.

12.What is the strength and rigidity of aircraft parts cnc machining, suitable for high load applications?

The ability of metal materials to resist elastic deformation under stress and The ability of metal materials to resist plastic deformation and fracture under external forces.

13.How do aircraft parts cnc machining handle the extrusion and removal processes of materials to meet design requirements?

aircraft parts cnc machining use a variety of tools and techniques to handle the extrusion and removal processes of materials. Depending on the material and design requirements, the machining process may involve cutting, drilling, milling, grinding, and other operations. For example, a CNC milling machine can be used to cut away excess material from a workpiece, while a CNC lathe can be used to shape and form the material. Additionally, CNC machining can be used to create complex shapes and features, such as threads, grooves, and other intricate details.